“Net emissions of CO2 by human activities — including not only energy services and industrial production but also land use and agriculture — must approach zero in order to stabilize global mean temperature.” — Steven J. Davis et al., Net-zero emissions energy systems

Introduction

While the majority of energy consumptions remains dependent on conventional fossil fuels such as oil, natural gas, and coal, the emergence of renewable energy sources — such as wind, solar, biomass, geothermal, and hydropower — offer a sustainable solution to the current energy crisis.

The Challenge

Our supply chains currently contribute to over 80% of greenhouse gas emissions. Clearly, the optimization of our supply chains’ energy consumption is a key issue to address in order to make substantial strides toward a greener future.

Linear Programming: A Powerful Optimization Method

This article presents an optimization method, known as Linear Programming, to optimize the integration of renewable energy into existing supply chain infrastructure. Linear Programming (LP) is a powerful mathematical optimization method developed during World War II. The method provides a systematic and rigorous framework to facilitate complex decision-making, modeling linear relationships among variables to find the optimal solution.

The LP framework is composed of:

- The objective function-the linear function to be optimized.

- Decision variables-the variables whose optimal values comprise the final solution.

- The constraints-a set of linear inequalities that represent the restrictions imposed on the decision variables.

The objective is to find the set of values at which the decision variables yield the optimal solution, as specified by the objective function within the bounds of the linear constraints.

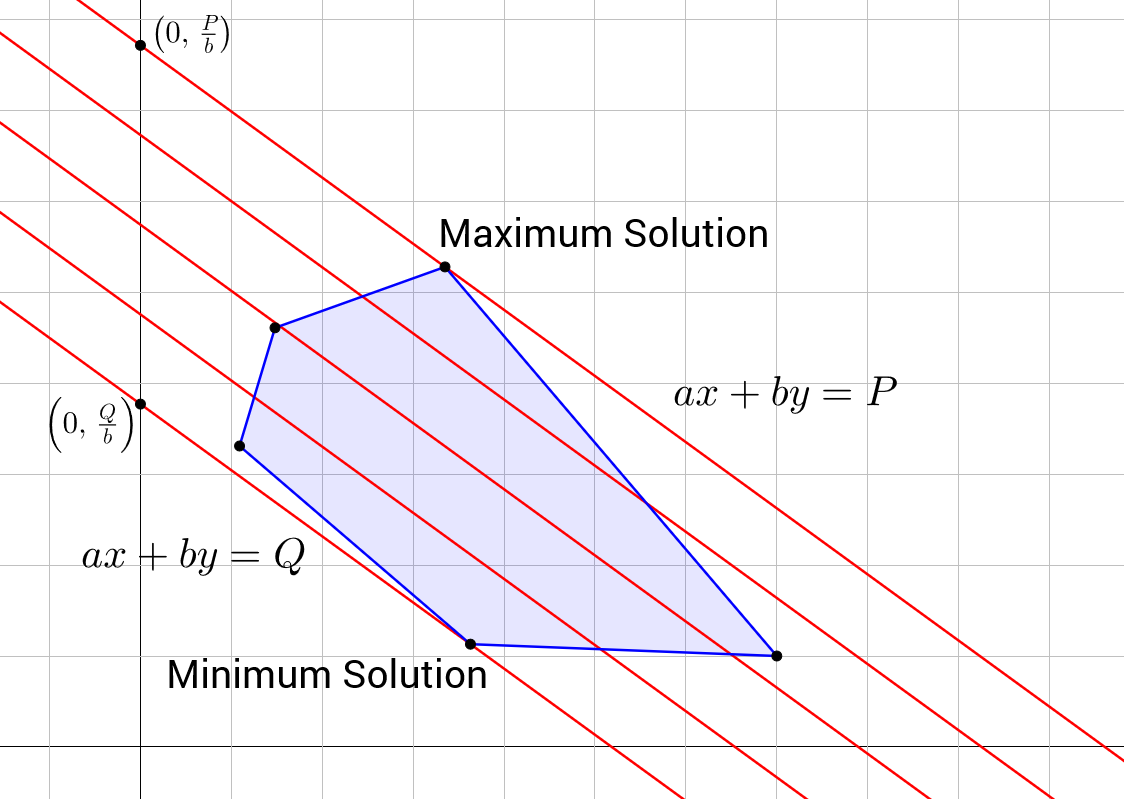

Simple 2-D linear programming problems can be solved graphically. This method offers a visual representation of the optimal solution, which can be found at the intersection of the linear objective function and the corner points of the feasible region. Pictured below, the red lines indicate the objective function’s level sets, which illustrate how varying decision variable values impact the final solution across differing expressions of the same objective function. The corner point selected as the optimal solution depends on whether we are maximizing or minimizing the objective function.

Case Study: Optimizing Renewable Energy Integration for a Multinational Computer Manufacturer Supply Chain

Now, let’s apply these principles to a more complex, real-world scenario. A large multinational company that manufactures computers currently consumes 100 MWh (megawatt– hours) of energy per day. Times are tough and the head of supply chain management has been granted just $25mil to reduce the company’s carbon footprint. Yikes! She is provided with the average estimated power output and cost estimates associated with implementing large, mid-size and small renewable energy power plants and tasked with maximizing the system’s renewable energy output.

Table 1: Megawatt-hours (expected value) produced by size j Power Plant powered by renewable energy source i

Table 2: Cost to build size j Power Plant powered by renewable energy source i

Leveraging Python’s PuLP Library for Optimization

To solve this problem, we can leverage Python’s PuLP library. This open-source resource provides a convenient and intuitive framework to formulate and solve optimization problems using Python.

# Install the library

# %pip install pulp

# Import the library

import pulp

# Formulate the problem

lp_problem = pulp.LpProblem('PowerGeneration', pulp.LpMinimize)

# Define the decision variables

## Size of Power Plant

sizes = ['Small', 'Mid-Size', 'Large']

## Type of Renewable Energy

sources = ["Hydropower", "Wind", "Solar", "Biomass", "Geothermal"]

x = pulp.LpVariable.dicts("Production", [(i, j) for i in sources for j in sizes], lowBound=0, cat=pulp.LpInteger)

# Generated power corresponding to each decision variable

gen_power = {

("Hydropower", 'Small'): 10,

("Hydropower", 'Mid-Size'): 20,

("Hydropower", 'Large'): 30,

("Wind", 'Small'): 0.25,

("Wind", 'Mid-Size'): 2,

("Wind", 'Large'): 3,

("Solar", 'Small'): 1,

("Solar", 'Mid-Size'): 5,

("Solar", 'Large'): 10,

("Biomass", 'Small'): 2,

("Biomass", 'Mid-Size'): 15,

("Biomass", 'Large'): 25,

("Geothermal", 'Small'): 8,

("Geothermal", 'Mid-Size'): 30,

("Geothermal", 'Large'): 50,

}

# Investment cost corresponding to each decision variable

inv_cost = {

("Hydropower", 'Small'): 2,

("Hydropower", 'Mid-Size'): 4,

("Hydropower", 'Large'): 6,

("Wind", 'Small'): 0.10,

("Wind", 'Mid-Size'): 1.5,

("Wind", 'Large'): 3,

("Solar", 'Small'): 1,

("Solar", 'Mid-Size'): 2,

("Solar", 'Large'): 3,

("Biomass", 'Small'): 1.5,

("Biomass", 'Mid-Size'): 2,

("Biomass", 'Large'): 3.5,

("Geothermal", 'Small'): 1,

("Geothermal", 'Mid-Size'): 3,

("Geothermal", 'Large'): 5,

}

# Define the objective function (maximize power)

objective = pulp.lpSum(gen_power[(source, size)] * x[(source, size)] for source in sources for size in sizes)

lp_problem += objective, "Maximize_Power"

# Define constraints

## Constraint 1: Total power generated must be at least 100

lp_problem += pulp.lpSum(gen_power[(source, size)] * x[(source, size)] for source in sources for size in sizes) >= 100, "Total_Power_Generated"

## Constraint 2: Total cost must be less than $25mil

lp_problem += pulp.lpSum(inv_cost[(source, size)] * x[(source, size)] for source in sources for size in sizes) < 25, "Total_Cost"

# Solve the linear programming problem

lp_problem.solve()To generate more detailed information about our solution, we can code:

# Check the status of the solution

if pulp.LpStatus[lp_problem.status] == 'Optimal':

print("Optimal Solution Found:")

# Initialize variables to store the total cost and power generated

total_cost = 0

total_power = 0

# Create a dict to store the breakdown of power sources and sizes

power_breakdown = {}

# Display the breakdown of power generated from each source

for source in sources:

for size in sizes:

source_power = x[(source, size)].varValue

if source_power > 0:

# Update the power breakdown dictionary

power_breakdown[(source, size)] = source_power

# Update the total cost and power

total_cost += inv_cost[(source, size)] * source_power

total_power += gen_power[(source, size)] * source_power

# Print the detailed power breakdown dictionary

for (source, size), power in power_breakdown.items():

print(f"{size} {source} power plants: {power}")

# Print the total power generated

print(f"Total Power Generated: {total_power} MWh")

# Print the total cost of the optimal solution

print(f"Total Cost: ${total_cost}mil")

else:

print("No Optimal Solution Found")This will give us our answers:

Optimal Solution Found.

- Small Wind power plants: 8.0

- Mid-Size Biomass power plants: 6.0

- Small Geothermal power plants: 1.0 units

______________________________

Total Power Generated: 100 MWh

Total Cost: $13.8mil

Coming in under budget?! Extra points.

Conclusion

By leveraging optimization techniques, we can address our toughest environmental and energy challenges. Supply chains, responsible for a significant share of greenhouse gas emissions, demand energy optimization. Linear Programming showcases math’s transformative potential, guiding us toward a cleaner, greener future.